If you’re comparing a p trap to an S trap, you’re already asking the right question—because the “shape” isn’t just cosmetic. The way a trap is built determines whether it keeps sewer gas out and whether it drains reliably without siphoning itself dry. In most modern plumbing systems, a p trap is the standard because it works with venting to protect the water seal that blocks odors and potentially hazardous sewer gases.

In this guide, you’ll learn what each trap does, why S-traps are widely prohibited, what plumbing codes typically require, and how to spot (and fix) common real-world issues.

What a plumbing trap does

A plumbing trap is a curved section of drain pipe designed to hold a small amount of water after the fixture drains. That standing water is called the trap seal. The trap seal is a simple but powerful barrier: it blocks sewer gases from traveling backward through the drain and into your home.

This matters because sewer gas can contain chemicals like hydrogen sulfide, which OSHA notes can cause serious health effects at high concentrations. The goal of any trap design is to keep that seal in place during normal use.

Most major codes standardize trap seals because too little water can evaporate or siphon out easily, and too much can affect performance. For example, federal manufactured-housing rules specify a p-trap water seal of not less than 2 inches and not more than 4 inches.

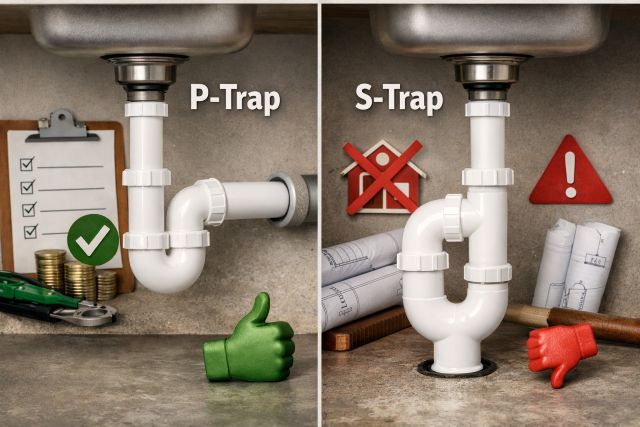

P trap vs S trap: the simplest definition

P trap: A U-shaped bend with a horizontal “trap arm” that runs to a vented drain line. Its layout helps prevent siphoning when properly vented.

S trap: A trap that drops vertically after the U-bend, creating an “S” shape. That vertical drop can encourage siphoning, which can pull the water seal out of the trap.

If you want the practical takeaway: a p trap is designed to work with venting; an S trap is more likely to lose its seal.

P trap vs S trap: key differences that affect performance

1) Drain path and siphoning risk

The biggest difference is what happens after the trap weir (the point where water spills out of the trap).

-

In a p trap, the fixture drains through the U-bend and then continues through a horizontal trap arm toward the wall. When the system is vented correctly, air enters behind the flow, helping prevent siphoning.

-

In an S trap, the outlet drops vertically. That drop can behave like a straw, pulling water behind it and increasing the chance of self-siphonage — meaning it can empty its own trap seal.

That’s why modern standards tend to prohibit S-traps (more on code below).

2) Venting compatibility

A p trap is the “default” trap design in modern DWV (drain-waste-vent) systems because it’s meant to be vented properly.

Federal rules for manufactured housing explicitly require fixtures to be trapped by approved water seal “P” traps and state that traps must be effectively vented.

S-traps, on the other hand, are often found in older homes or DIY installs where proper venting is missing or the layout doesn’t allow a correct trap arm-to-vent relationship.

3) Likelihood of sewer gas odors

Odors usually show up when the trap seal is compromised. That can happen due to:

-

siphoning (more common with S-traps)

-

evaporation (common in floor drains, guest baths, and unused fixtures)

-

pressure fluctuations in poorly vented systems

Since S-traps are more prone to siphoning, they’re more likely to lead to “mystery smells,” especially after a big discharge (like draining a full sink quickly).

Pros and cons of a p trap (real-world view)

Pros

-

Code-aligned in modern installations (with correct venting)

-

More stable trap seal because it’s less prone to self-siphoning

-

Easier troubleshooting: standard parts, familiar to plumbers, widely supported configurations

-

Works well with trap-seal protection methods in situations where evaporation is a risk (like floor drains)

Cons

-

Requires correct slope and trap arm geometry; a sloppy install can still siphon or gurgle

-

Space can be tight under some fixtures (vanities, pedestal sinks), tempting DIYers to “make it fit” with bad layouts

Pros and cons of an S trap (why it still shows up)

Pros

-

It can be a convenient shape when the drain outlet is in the floor and someone wants a quick connection

Cons (the important part)

-

Higher siphoning risk, which can drain the trap seal and allow sewer gas in

-

Often not compliant with modern codes in new work

-

Can cause gurgling, slow drainage, and recurring odor complaints that feel “random” to homeowners

Plumbing code rules: why S-traps are typically prohibited

Many modern codes prohibit S-traps because they are more likely to lose the trap seal under normal discharge conditions.

One clear example appears in an IAPMO Uniform Code Spotlight quoting the UPC training material: “S” traps … shall be prohibited (along with certain other trap types).

You can also see similar prohibitions in federal standards: 24 CFR 3280.606 lists full “S” traps among prohibited traps and requires approved water seal “P” traps.

In plain language: if a trap design makes it easier to lose the seal that blocks sewer gas, codes move away from it.

Plumbing code rules: p trap basics you should know

While local rules vary, many widely used standards share common principles:

Trap seal depth (the “2 to 4 inch” rule)

Multiple authoritative sources align on a typical requirement that fixture traps maintain a liquid seal in the 2 inch to 4 inch range.

-

Federal manufactured-housing standards specify 2″–4″ for p-trap water seals.

-

IAPMO materials also discuss this range as an optimum seal depth for balancing protection and performance.

Venting requirement

The trap is only half the system. Venting is what prevents pressure swings from siphoning or blowing the seal. Federal rules for manufactured housing explicitly note that traps must be effectively vented.

Prohibited trap types (beyond S-traps)

Codes often prohibit trap designs that rely on moving parts or concealments to maintain a seal, because reliability matters over the long run.

“But my sink has an S-trap and it works” — common scenarios

Scenario A: It “works,” but smells sometimes

This is classic: the sink drains fine most days, but you occasionally notice sewer odor—often after draining a full basin quickly. That can happen when the S-trap self-siphons and partially (or fully) loses its seal.

Scenario B: Gurgling after the sink drains

Gurgling often indicates pressure imbalance and air being pulled through water. With an S-trap, siphoning is more likely, and the gurgle can be the sound of the system trying to “find air” through the trap.

Scenario C: Older home, floor outlet, limited wall access

This is where S-traps commonly survive. The drain is in the floor, and a quick retrofit created the S-shape because it was the easiest connection — especially in bathrooms with pedestal sinks.

How to tell if you have an S-trap or a p trap (quick visual)

-

P-trap: you see the U-bend, then a horizontal run into the wall.

-

S-trap: you see the U-bend, then it continues downward into the floor (often with little to no horizontal trap arm).

If the pipe goes down after the bend, be suspicious. If it goes sideways toward the wall, it’s more likely a p trap.

Fixing an S-trap the right way (high-level guidance)

The most common code-compliant fix is to convert the setup so the trap has a proper trap arm and venting relationship — usually by:

-

re-routing the drain to create a true p trap configuration

-

ensuring there’s a proper vent connection (or an approved alternative where allowed)

Because venting rules and allowable alternatives vary by jurisdiction, treat this as a “talk to your local code / licensed plumber” moment if you’re doing more than a simple like-for-like replacement.

Trap seal loss isn’t only siphoning: evaporation is a big deal too

Even a perfectly installed p trap can lose its seal through evaporation if a fixture isn’t used for a long time — especially floor drains, basement showers, or guest bathrooms.

There’s published building-services research noting that seal water can be lost by multiple mechanisms, with evaporation and induced siphonage being major factors in seal loss.

In practical terms: if a drain is rarely used, run water occasionally to restore the seal, or consider trap-seal protection devices where permitted.

FAQ

What is a p trap?

A p trap is a curved plumbing fitting that holds water to block sewer gas while allowing wastewater to drain. It’s shaped like a “P” on its side and is designed to work with venting to protect the trap seal.

Why are S-traps not allowed in many plumbing codes?

Many codes prohibit S-traps because their vertical drop can siphon water out of the trap, breaking the seal that blocks sewer gas. For example, UPC training material states “S” traps are prohibited.

What is the typical required trap seal depth?

Common requirements set the trap seal between 2 inches and 4 inches. Federal manufactured-housing rules specify this range for p-traps.

Can a p trap still smell?

Yes. A p trap can smell if the seal evaporates (rarely used drain), is siphoned due to poor venting, or if there’s buildup/biofilm in the trap. Restoring water to the trap and checking venting are common first steps.

Is an S-trap ever acceptable?

In most modern new-work situations, it’s typically not. Some older homes may still have them, but renovations often trigger requirements to bring plumbing up to current standards.

Actionable tips to keep your p trap working properly

-

If a drain is rarely used, run water periodically to maintain the seal (especially floor drains).

-

If you hear gurgling or smell odors, suspect venting or trap seal issues—not just “dirty pipes.”

-

Avoid DIY “space-saving” trap hacks that remove the proper trap arm or create an S-shape.

Conclusion: choosing the p trap (and doing it in a code-smart way)

When it comes to p trap vs s trap, the p trap wins for one core reason: it’s built to keep the trap seal stable when paired with proper venting. That stability is exactly why modern standards and regulations commonly prohibit full S-traps and require approved p-trap installations.

If you’re remodeling, troubleshooting odors, or correcting an older setup, treating the p trap as the default choice — and ensuring the drain is properly vented and sealed — will give you the most reliable, code-aligned result.