A blind flange is the simplest-looking flange you’ll ever buy, and one of the easiest to get wrong.

Unlike weld neck or slip-on flanges, a blind flange has no bore. It’s a solid disk designed to close off the end of a piping run, a valve, or a pressure vessel nozzle. That “solid disk” job sounds straightforward, but sizing, facing, bolting, gasket selection, and pressure-temperature derating are where real projects succeed or fail.

In this guide, you’ll learn how blind flange specifications work, what “standard sizes” really mean, how pressure ratings are determined, and how to choose a blind flange that seals reliably in the real world.

What is a blind flange?

A blind flange is a pipe flange used to seal a pipeline or equipment opening by bolting a solid plate to a mating flange with a gasket in between. Because it must resist full internal pressure without the benefit of a pipe bore, it often needs greater thickness and careful bolting compared to many other flange types.

In most industrial projects, blind flanges are specified by a governing standard (such as ASME B16.5 or ASME B16.47), a size (NPS or DN), a pressure class (such as Class 150 or Class 600), a facing type (RF, FF, RTJ), and a material specification (such as ASTM A105, A182 F304/F316, etc.). ASME’s standard pages are the best “source of truth” for scope and size ranges.

Why blind flange selection matters more than it seems

Blind flanges show up everywhere: maintenance isolation points, future tie-in locations, hydrotest blinds, dead legs, and equipment nozzles. A mismatch in facing, bolt pattern, or pressure-temperature rating can create delays, expensive rework, or leaks.

Industry guidance on bolted flange joint assembly exists for a reason: leakage in bolted joints is widely recognized as a common and persistent reliability issue, and the assembly method (bolt load, pattern, lubrication, and gasket compression) is critical to getting a tight seal.

The key blind flange standards and what each covers

ASME B16.5 blind flange specifications

ASME B16.5 is the most common reference for pipe flanges in process piping. It covers flanges in sizes NPS 1/2 through NPS 24 for rating classes 150, 300, 400, 600, 900, 1500, and also Class 2500 in smaller sizes (the B16.5 scope explicitly notes Class 2500 coverage up to NPS 12 for certain flange types).

If your project says “blind flange, ASME B16.5,” you’re working in that NPS 1/2–24 universe, and you should expect pressure-temperature ratings to come from B16.5 tables that depend on material group and temperature.

ASME B16.47 blind flange specifications for large diameter

When you move into large diameters, ASME B16.47 comes into play. It covers NPS 26 through NPS 60, with pressure classes that include 75, 150, 300, 400, 600, and 900, and it includes blind flanges in its scope.

B16.47 is also where you’ll encounter Series A and Series B. In practice, these series differ in dimensions (especially bolt circle and drilling), so “NPS 36 Class 150 blind flange” is not complete unless the series is identified.

Series A vs Series B

Series A is historically aligned with MSS SP-44, while Series B is associated with API 605 lineage, and B16.47 incorporates that heritage. A practical takeaway is that bolt circles and drilling can differ between Series A and Series B at the same nominal size and class, so the flanges will not necessarily mate.

EN 1092-1 blind flange specifications (common in EU/metric projects)

For projects based on European standards, blind flanges may be specified to EN 1092-1 (often Type 05 for blinds), using PN ratings rather than ASME Class ratings. EN 1092-1 documents cover flange types, dimensions, and pressure classes across PN ranges.

If your plant uses mixed equipment (some ASME, some EN), you must explicitly identify which standard governs the blind flange to avoid bolt pattern conflicts.

Blind flange sizes: what “standard size” actually means

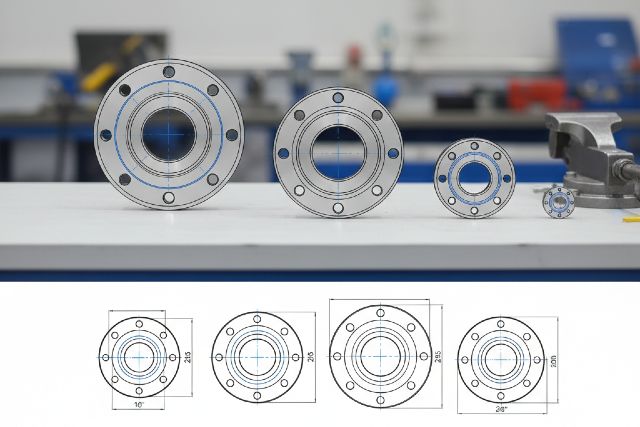

Blind flange size is usually given as NPS (Nominal Pipe Size) in ASME systems or DN (Nominal Diameter) in EN systems. Here’s the part that trips people up: NPS and DN are nominal designations, not literal measurements of outside diameter.

For ASME B16.5 blind flanges, you’ll see sizes from NPS 1/2 up to NPS 24, with each size tied to standardized outside diameter, thickness, bolt circle diameter, number of bolt holes, and bolt hole diameter per class.

For ASME B16.47, sizes run NPS 26 to 60, again with standard bolt patterns and thickness by series and class.

A quick reality check on fit-up

A blind flange must match its mating flange in three ways:

It must match the nominal size (NPS/DN), so the outside diameter and bolt circle line up.

It must match the pressure rating system (ASME Class or EN PN), so the drilling pattern and thickness expectations align.

It must match the facing type, so gasket seating behavior is correct.

When one of these doesn’t match, installers often try to “make it work” on site. That’s how you end up with uneven gasket compression and chronic seepage.

Facing types: RF, FF, and RTJ

Blind flanges are manufactured with a flange face that dictates how the gasket seals.

Raised Face (RF) is extremely common in ASME B16.5 and many process services. It uses a gasket that sits inside the bolting circle.

Flat Face (FF) is often used with certain cast iron components or where the mating flange requires it. Mixing FF and RF is not a casual decision; it changes gasket compression and can overstress weaker mating flanges.

Ring Type Joint (RTJ) is used in high-pressure and critical services, relying on a metal ring gasket in a machined groove for robust sealing.

Your flange standard and service requirements typically drive the face, but the mating flange is the final authority. If the nozzle is RF, your blind flange should be RF. If it’s RTJ, match RTJ groove details precisely.

Pressure ratings: what “Class 150” really means

This is the part most people oversimplify. ASME “Class” numbers are not a direct PSI rating. They are rating designations that map to allowable pressure at a given temperature for a given material group.

ASME flange standards provide pressure-temperature rating tables. That means the same “Class 600” blind flange can have different allowable pressures depending on the material group and the operating temperature.

ASME B16.5’s available rating classes include 150, 300, 400, 600, 900, 1500, and 2500, and these are explicitly discussed as the standardized rating designations used for B16.5 flanges.

ASME B16.47 similarly defines pressure classes in its scope for large diameter flanges, including Class 75 and up to Class 900.

Temperature derating is the hidden trap

Pressure ratings drop as temperature rises because material strength decreases. In practical terms, you can’t choose a blind flange by “pressure only” without checking the temperature column in the rating table for the correct material group.

Engineering references built around the ASME rating tables emphasize this derating behavior and highlight that allowable pressure can drop dramatically at elevated temperatures for the same class.

If you’re working in hot service, this is where many underspecified blinds come from: the designer selects Class 300 based on ambient intuition, but the line runs near a temperature where the allowable pressure is much lower than expected.

Blind flange thickness: why it varies by class and standard

Blind flange thickness is not arbitrary. Standards define minimum thicknesses by size and class because a blind flange behaves like a plate under pressure and must control stress and deflection.

For ASME B16.5, published dimension references show thickness values that increase as you go up in class for the same NPS.

For ASME B16.47, thickness is also standardized, but differs by Series A vs Series B in many sizes.

In real projects, “special thickness” blinds are sometimes specified for unusual loads or to reduce deflection in sensitive gasketed joints. If you go off-standard, treat it as an engineered design item, not a casual procurement tweak.

Materials: matching strength, corrosion resistance, and code requirements

Blind flanges come in a wide range of materials, and your choice should be driven by process fluid, corrosion allowance, operating temperature, and code requirements.

In ASME systems, the pressure-temperature rating tables depend on material grouping, so material selection directly impacts allowable pressure at temperature, not just corrosion resistance.

Common project patterns look like this:

Carbon steel (often specified via ASTM forging standards) for general hydrocarbons and utilities where corrosion is controlled.

Stainless steels (various grades) for corrosive media or where cleanliness matters.

Alloy steels for higher temperature service where strength retention is required.

The safest workflow is to start with the piping material class (line class) or the equipment nozzle material, then select the blind flange material to match the governing spec so rating tables and corrosion expectations remain consistent.

How to read a blind flange specification line item

A typical purchase description might look like:

“Blind flange, ASME B16.5, NPS 8, Class 600, RF, ASTM A105, NACE compliant, ANSI B16.5 drilling”

Even without a table, that line includes nearly everything procurement and fabrication needs. What it does not include, and what engineers should still verify, is the pressure-temperature suitability at the operating temperature for the specific material group used in the standard tables.

Real-world scenario: the “matches on paper” blind that still leaks

Here’s a common field story.

A unit has an RF blind flange installed on a seldom-used future tie-in. The blind matches NPS, class, and bolt pattern. During a turnaround, the team removes and reinstalls it, but it seeps during startup.

What happened? Very often it’s assembly and gasket stress, not the basic dimensions. Industry guidance exists precisely because bolted flange joints are sensitive to bolt load, lubrication assumptions, tightening sequence, and gasket selection, and leakage is frequently tied to these practical factors.

Actionable fix: treat reassembly like a critical joint. Use controlled tightening methods aligned with recognized guidance (such as PCC-1 style practices), confirm gasket condition and compatibility, and ensure the flange faces are clean and not damaged.

Choosing the right blind flange pressure rating, step by step

Start with your design pressure and design temperature, not operating conditions. Then confirm which standard governs the piping class or nozzle.

If the size is NPS 24 or smaller, ASME B16.5 is typically your default in ASME-based plants.

If it’s NPS 26 or larger, ASME B16.47 becomes relevant, and you must specify Series A or Series B.

Next, select the material and verify the allowable pressure at design temperature using the correct pressure-temperature tables for that material group. This is where “Class 300” becomes a real number for your exact service.

Finally, confirm facing type and gasket selection as a matched pair with the mating flange.

FAQ: blind flange specifications, sizes, and ratings

What is a blind flange used for?

A blind flange is used to close off the end of a pipe, valve, or nozzle by bolting a solid flange plate to a mating flange with a gasket. It’s commonly used for isolation, maintenance, future tie-ins, and hydrotesting.

Are blind flange pressure classes the same as PSI?

No. ASME “Class” numbers are rating designations tied to allowable pressure at specific temperatures for specific material groups, using pressure-temperature tables in the standard.

What sizes do ASME blind flanges come in?

ASME B16.5 covers NPS 1/2 through NPS 24 (with class coverage defined in the standard scope). ASME B16.47 covers large diameter flanges from NPS 26 through NPS 60 and includes blind flanges.

What’s the difference between ASME B16.5 and ASME B16.47 blind flanges?

B16.5 is the common standard for NPS 1/2–24. B16.47 applies to NPS 26–60 and introduces Series A and Series B dimensional systems, which can affect bolt patterns and interchangeability.

Can I mate a Series A blind flange to a Series B flange?

Not reliably. Series A and Series B can have different drilling and bolt circle dimensions at the same nominal size and class, so you must specify the series to match the mating flange.

Do I always need a gasket with a blind flange?

In standard bolted flange joints, yes. The gasket provides the seal between the flange faces. Seal performance depends heavily on assembly practices and achieving correct bolt load.

Conclusion: picking the right blind flange with confidence

A blind flange is a pressure boundary component, not just a “cap.” To specify it correctly, you need to align the governing standard (ASME B16.5 for common sizes or ASME B16.47 for large diameters), the size (NPS/DN), the facing type, and the pressure class while confirming pressure-temperature ratings for the actual material at the actual design temperature.

If you take one practical lesson from this guide, let it be this: most headaches come from incomplete specs and assumptions about ratings. When you state the full spec and treat assembly as part of the engineering system, your blind flanges stop being a recurring leak point and start behaving like the reliable isolation devices they’re meant to be.